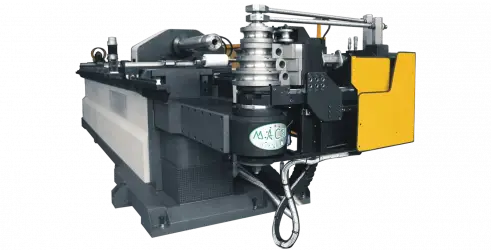

MACRI CNC TUBE BENDING MACHINES

1 to 12 axes tube benders

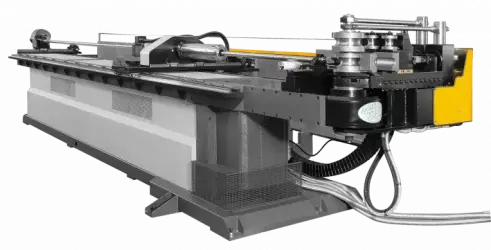

Macri Italia production comprises 8 series of tube bending machines, each having different tube dimensions and thus different bending capacities.

Indeed, one of the most important variables when choosing a machine is the diameter of the tube to be bent, which – according to the Macri Italia classification system – can be of:

- up to 114 mm » Series 114

- up to 90 mm » Series 90

- up to 65 mm » Series 65

- up to 45 mm » Series 45

- up to 35 mm » Series 35

Macri Italia can produce 1 to 12 axes electric bending machines, depending on the level of automation and the product that is to be produced. The most popular are the EURO (1 axis), PROFAST (3 axes), PROVAR 5 (5 axes), PROVAR 6 (6 axes), PROELECT (10 axes) and PROSPACE (12 axes) tube benders.

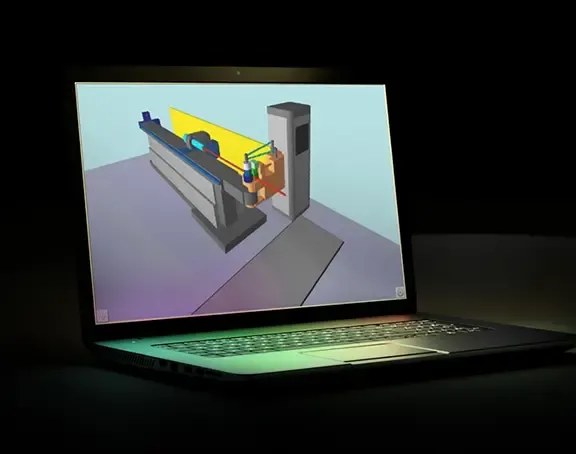

Thanks to the extensive experience of its technicians, Macri Italia also produces special tube bending machines that are especially modified to meet the customer's production needs.

All Macri machines use IRMCO high-tech, environmentally friendly lubricants

Find out moreProelect

45 to 10 axes full electric

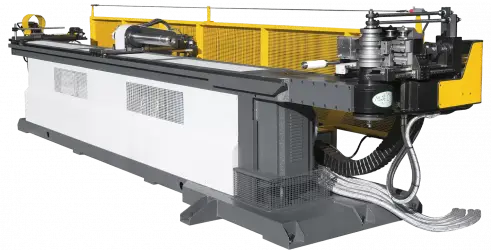

Series 114

Series 114 is the range of machine bending tubes that allows large tubes up to 114 mm in diameter, generally used in the rough framing sector.

Series 90

Series 90 is the range of machine bending tubes that allows large tubes up to 90 mm in diameter, generally used in the rough framing sector.

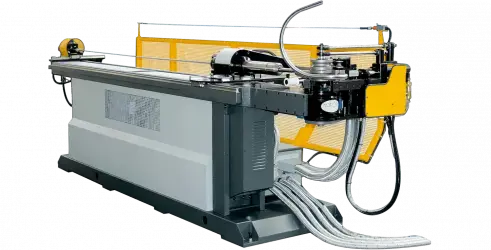

Series 65

Series 65 comprises 1 to 6 axes electric tube bending machines that are capable of bending tubes up to 65 mm in diameter: an important dimension that does not however prevent the design of an extremely versatile tube bender.

Series 45

Series 45 comprises 1 to 6 axes tube bending machines that are capable of bending tubes up to 45 mm in diameter.

Series 35

Series 35 comprises 1 to 6 axes tube bending machines that are capable of bending tubes up to 35 mm in diameter.

Bending Machine Special

Macri Italia is also able to design and produce special tube bender, for each series by modifying the structure on the basis of the customer's specific production needs.